DEPARTMENTS AND PROCESSING

THE BERO PRODUCTION

DYNAMISM - ORGANIZATION - QUALITY

The Bero plant expresses production efficiency and technological precision, orchestrated to meet the needs of a B2B market made up of medium and large customers. At the heart of this plant is the technical office, where the accurate management of orders initiates a meticulous and coordinated processing cycle that involves the four main departments: Gearing, CNC Milling, Pantographs and Turning.

TEAM OF SPECIALISTS

Each department, equipped with cutting-edge machinery and led by a team of specialists, helps transform raw materials into high-quality components, respecting rigorous standards of precision and reliability.

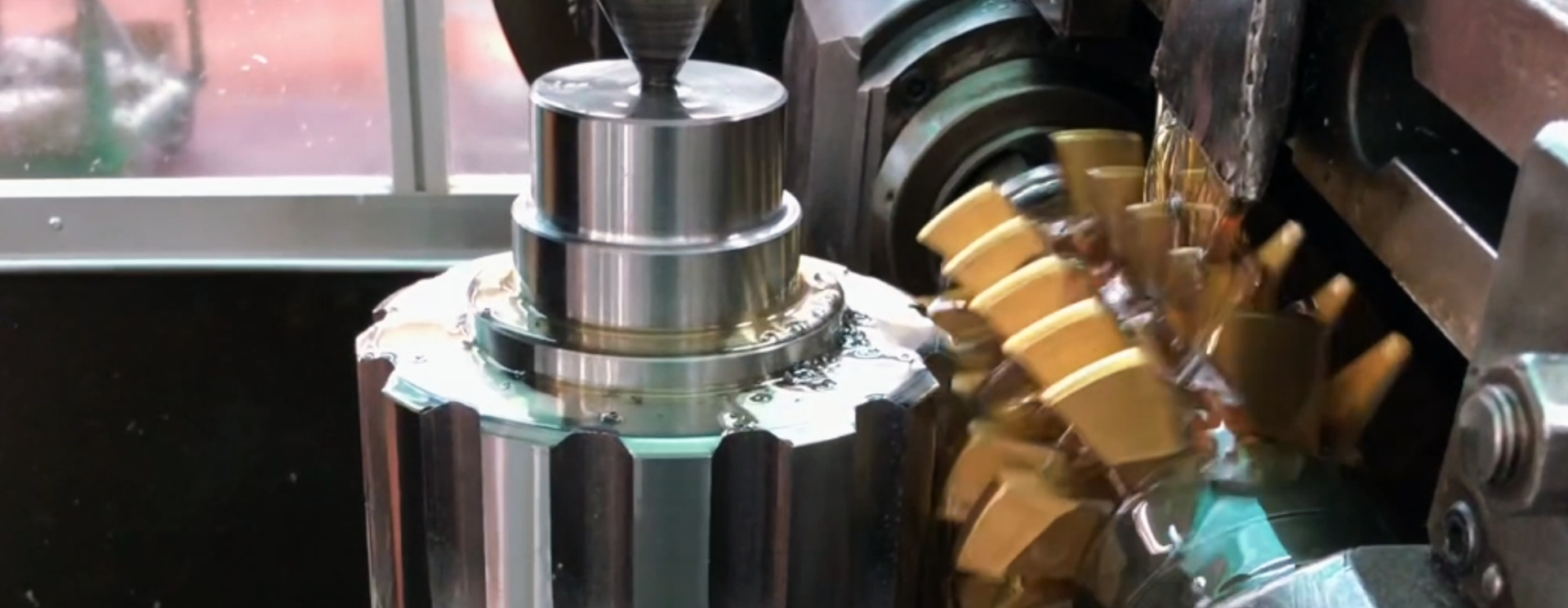

The gearing department, with its expertise in the processing of gears and cogwheels, is the first step in a cycle that sees the transformation of raw materials into sophisticated mechanical components. This is followed by the CNC Milling department, where advanced technologies such as the HURCO and OMV BFC 1300 machining centers precisely model both metals and plastic materials.

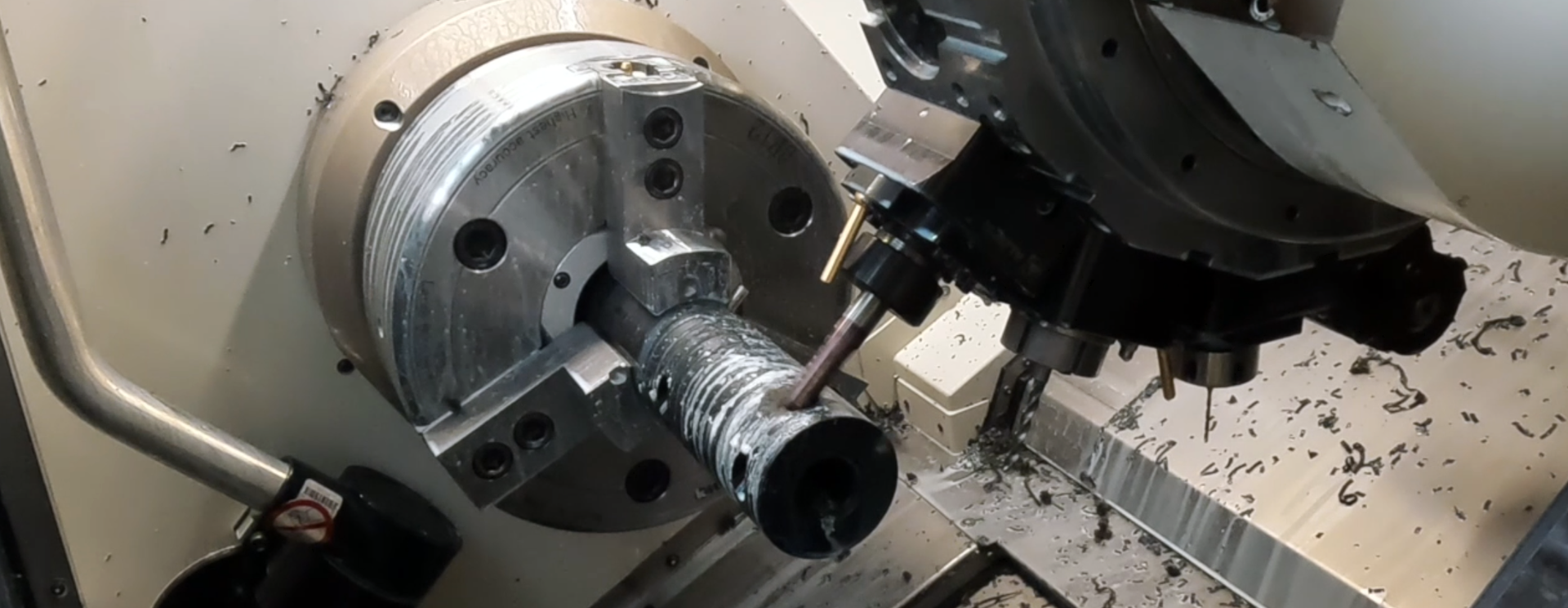

In the Pantograph department, machines such as the Protek Compact and the various SCM Accord models process aluminium, Dibond and plastic materials, reflecting the versatility and adaptability of the production process. Finally, the Turning department, with its Doosan Puma and Biglia B750YS CNC lathes, completes the cycle with the fine and detailed processing of the parts.

WELL-STOCKED RAW MATERIALS WAREHOUSES

Supporting this production process is a large warehouse of raw materials, ensuring that production proceeds smoothly and without delays due to supply shortages. This warehouse, together with careful production planning, allows Bero to respond quickly to various customer needs, while maintaining a high quality of the finished product.

In parallel, the finished products warehouse plays a crucial role in logistics, ensuring that each component is ready for shipment and delivered on time, consolidating Bero's reputation as a reliable and punctual partner.

In summary, Bero production is a model of high-level industrial engineering and management, each phase of the production cycle is optimized to maximize efficiency and quality. The success of this organization is reflected not only in customer satisfaction, but also in the prominent position that Bero holds in the B2B market.